BASF Tinuvin 123 Light Stabilizer

Product introduction

TINUVIN 123 is a new type of liquid hindered amine light stabilizer, PH is neutral to avoid reacting with the acid catalyst in the coating. It can protect the coating from cracking, tarnishing and other minor changes.

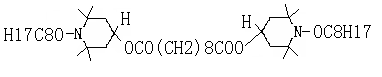

chemical structure

physical properties

|

Exterior |

clear yellowish liquid |

|

Dynamic viscosity 20℃ |

2900-3100 mPa.S |

|

Density 20℃ |

0.97g/cm3 |

|

Solubility at 20°C (g/100g solvent) |

Soluble (more than 50%) in common coating solvents, solubility in water is less than 0.01% |

Scope of application

TINUVIN 123 is recommended for: automotive paints, industrial paints, decorative paints, wood paints, varnishes, etc.

TINUVIN 123 is suitable for high solids, acid catalyzed automotive and industrial paints such as two-pack heat-curing acrylic metallic paint systems, one-pack heat-curing acrylic, polyester coatings.

TINUVIN 123 has demonstrated efficient photostability in the following applications:

Air-drying automotive refinish coatings based on alkyd/acrylic systems

Air-drying alkyd paint, varnish

Two-component PU paint

Liquid TINUVIN 123 is also readily compatible with aqueous systems.

TINUVIN 123 can form a synergistic effect with UV absorbers for better results:

In automotive paints, it can be added together with UV absorber TINUVIN 1130 to achieve a good anti-erosion effect, and has a good protective effect on gloss retention, chalk resistance, discoloration resistance and delamination resistance. The light stabilizer can be added to the two-component primer and varnish of the automobile; in the wood paint, TINUVIN 123 can be added to the air-drying paint of the alkyd system together with the UV absorber 1130.

Recommended addition amount (based on the solids content of the coating system)

Automotive paint, industrial paint 0.5-2.0% TINUVIN 123

Compounding

1-3.0% TINUvin 1130

Wood Lacquer 0.5-2.0% TINUVIN 123

Use alone or in combination

1-3.0% TINUvin 1130

safety guide

TINUVIN 123 refers to general industrial operation. Please refer to the safety data sheet for specific data.