PF-1069 Easy-to-clean hydrophobic and oleophobic nanocoating

Model

PF-1069D (base coat)/PF-1069M (top coat)

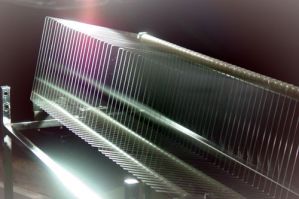

Type Easy-to-clean hydrophobic and oleophobic nanocoating

application

Steel, aluminum and other metal materials; plastics, textiles, leather, wood, shoes; communication tower antennas, military and civilian radars; anti-icing power lines; anti-icing peeling coatings for wind turbine blades; mesa.

Main features

- Self-cleaning: resistant to water and oil pollution, dry and sterile, easily removes dust and dirt from the surface

- Anti-pollution: greatly reduce or eliminate the pollution of dust and dirt, water and liquid containing bacteria or radiation

- Corrosion resistance: water and water vapor in the air do not really touch the surface, greatly reducing the corrosion of objects

- Antifreeze: the surface of the object is dry without moisture and will not freeze

- Moisture-proof: keep the object dry, and many liquids such as water are difficult to absorb

- Wide range of application: from -30°C to 50°C

Product Specifications

|

project |

Technical indicators |

Detection method |

|

color and appearance |

Transparent flat smooth color |

Visual inspection |

|

coating |

Primer + Top coat |

|

|

Theoretical coating area |

About 6㎡/kg |

GB/T 6753-1986 |

|

curing temperature |

Room temperature self-drying |

GB 1728-1989 |

|

Primer 20-30min, topcoat 5-10min |

||

|

hydrophobic angle |

>150° |

|

|

oleophobic angle |

>150° |

|

|

anti-UV |

12 months |

|

|

adhesion |

Level 1 |

GB/T 1731-1993 |

|

flexibility |

1mm |

GB/T 1732-1993 |

|

impact strength |

≥25kg.cm |

GB/T 1732-1993 |

|

dry film thickness |

10-25μm recommended |

|

construction technology

Pre-construction treatment Before spraying, the surface of the coated object should be treated to remove the residual paint film, rust, oil, oxide scale and sundries on the surface. It is required to achieve no rust, no oil, no dust and no water marks. The cleaned surface should be sprayed in time to prevent dust from reappearing. The construction environment is required to be dust-free, with exhaust devices or corresponding air-cleaning equipment to ensure construction quality.

The coating should be fully stirred before use, and the construction can be carried out by air spraying.

Spray pressure: 0.138-0.241MPa, nozzle diameter: 0.5-1.27mm, spraying distance: 15-25 cm, recommended film thickness: 10-25 μm, construction temperature: 10-30℃, relative humidity: 45-75%

The primer coating should be fully stirred before use. It can be applied by air spraying. It must be sprayed with HPLV gun, and sprayed thinly and evenly for several times. After drying, the thickness of the coating is 10-25 μm. After the coating is dry, spray the topcoat, and consider using a heat gun and blower to speed up the drying of the primer.

Surface coating The surface coating cannot use the same spray gun as the base coating. To choose a new spray gun, it must be sprayed with an HPLV gun, and sprayed thinly and evenly for many times. After drying, the thickness of the coating is 10-25 μm, using the same amount to cover the base coat.

Drying/Curing Method The superhydrophobic properties of the coating will appear 30 minutes after the surface coating is applied. The best time is after 2 hours.

Maintenance and Maintenance

The superhydrophobic and superoleophobic nanocoatings (self-drying at room temperature) must use both coatings to exhibit superhydrophobicity and superoleophobicity. Resistant to oil-water mixtures and oils when the coating is fully cured. Please use low-pressure water spray to clean the surface, the surface will be self-cleaning under the low-pressure water flow, dust and dirt will be easily washed away, and the surface will remain completely dry.

Material Safety

A Material Safety Data Sheet for this product is available upon request.

storage

Store at 18-25°C, use period of 6 months.