PF-1033H Water-based bright and wear-resistant varnish

Product introduction

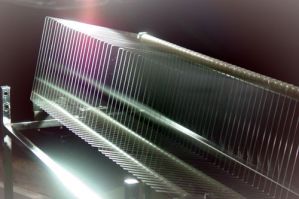

This product is a high performance aliphatic waterborne polyurethane dispersion and crosslinking reaction two-component waterborne bright paint, suitable for the protection and decoration of various paper, film, plastic and other substrates, with good chemical resistance and Toughness, plasticizer migration resistance, short drying time, excellent water resistance, excellent abrasion resistance.

Printing glazing can enhance the light resistance of the ink, increase the heat and moisture resistance of the ink layer, and play the role of protecting the imprint, beautifying the product, and replacing the film. Compared with lamination, printing glazing is simple in process and cost-effective. It can be full-plate glazing or partial glazing, and it meets the requirements of environmental protection regulations.

Product parameters

|

project |

unit |

Numerical value |

|

Appearance (25℃) |

- |

milky white solution |

|

Active ingredients |

% |

30±3 |

|

PH |

- |

8.0±0.5 |

|

proportion |

g/cm³ |

1.050 |

|

Viscosity |

s |

50-120 |

application process

●Coating method: screen printing, spraying, blade coating, roller coating

Drying conditions: self-drying at room temperature for 7 days or 80-90℃/2 hours drying

●Construction process: spraying example

● Stir the varnish evenly, and weigh it according to the ratio of paint: curing agent: water = 100 : (1-3) : (10-20). Mix the well-measured varnish evenly, test the viscosity for 12-17s, leave it for 10 minutes, and then spray it for use.

漆膜性能

|

||||||||||||||||||||||||||||

Precautions

Please prepare and use the varnish now, do not leave it overnight. Unused varnish should not be returned to the original paint bucket. Please seal tightly after opening and use up as soon as possible. Under the condition of not higher than 25℃, the original product can be stored stably for 180 days, the minimum storage temperature: 5℃. Do not apply below 5°C.