BASF Tinuvin 5050 Light Stabilizer

Product introduction

TINUVIN 5050 is a composite light stabilizer used in the coatings industry. Its excellent thermal stability and environmental durability make it suitable for protecting high-temperature baking systems and industrial coatings used in extremely harsh conditions. Based on its wide absorption wave range, TINUVIN 5050 can impart effective protection to photosensitive substrates such as wood and plastic. Protect.

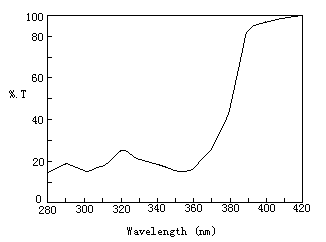

absorption spectrum

Toluene solvent, cell thickness 1CM, maximum absorption wavelength 346nm

physical properties

|

Exterior |

amber viscous liquid |

|

Dynamic viscosity 20℃ |

900mPa.S |

|

Density 20℃ |

1.03g/cm3 |

|

TINUVIN 5050 is miscible with most organic solvents for coatings at a ratio of more than 50%, but the solubility in water is less than 0.01%. |

|

Scope of application

TINUVIN 5050 is a general-purpose light stabilizer. Suitable for varnishes, paints, waterborne and solventborne systems. The additive is especially recommended for clearcoats and light-colored paints such as:

Wood coatings (especially waterborne acrylic dispersions)

One-component or two-component PU coating

Polyester/Isohydroester System

Car Wax, Car Polishing Oil, and Vinyl Insecticide

Unsaturated polyester/styrene system gel coat

UV curable acrylic and unsaturated polyester systems

Before adding TINUVIN 5050 into an aqueous system, it should be mixed with a water-miscible solvent such as butyl diethylene glycol.

Recommended addition amount (based on the solids content of the coating system)

|

wood coatings |

2-4% |

|

Home and Decorative Paints |

%w/w |

|

One-pack or two-pack polyurethane coatings |

19 |

|

Industrial baking paint |

57 |

|

Unsaturated polyester/styrene system gel coat |

57 |

|

UV curable acrylic and unsaturated polyester systems |

38 |

|

Paint car wax, car polish and vinyl insecticide |

32 |

The specific dosage should be subject to the actual test effect.

safety guide

TINUVIN 5050 refers to general industrial operation. Please refer to the safety data sheet for specific data.