Photoinitiator 1173 for UV radiation curing systems

Product introduction

Photoinitiator 1173 is a liquid type, non-yellowing photoinitiator. It was first proposed by Merck in the 1980s under the original name DAROCUR 1173. Good solvency makes it ideal for making photoinitiator mixtures. It is the first choice for making inks for wood, metal and plastic, as well as UV-curable adhesives.

physical parameters

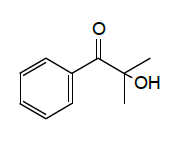

|

structure |

|

|

Chemical Name |

2-Hydroxy-2-methyl-1-phenyl-propan-1-acetone(2-羟基-2-甲基苯酮) |

|

CAS No |

7473-98-5 |

|

EINECS No |

231-272-0 |

|

molecular formula |

C10H12O2 |

|

molecular weight |

164.2 |

|

Exterior |

Colorless to pale yellow clear liquid |

|

odor |

very faint smell |

|

melting point |

ca. 4 °C |

|

boiling point |

80-81℃@1 mmHg, 250℃@760 mmHg |

|

proportion |

1.074 @20℃ |

Soluble

Insoluble in water, soluble in most organic solvents; compatible with most unsaturated prepolymers, resins and monomers used in UV curing industry.

Specification

|

Exterior |

light yellow clear liquid |

|

Assay |

98.0% min |

|

Determination of boiling point |

105 - 115℃ @3 - 5 torr |

|

Volatile content |

Up to 0.5% |

|

Solubility |

clarify |

application

Under the irradiation of ultraviolet light, the photoinitiator 1173 undergoes iso-decomposition and intramolecular destruction to generate a pair of free radicals, thereby triggering the polymerization of the ultraviolet curing system. It doesn't need a hydrogen donor to start its free radicals. But its free radicals are very sensitive to oxygen in the air. It was the first initiator for non-yellowing clear coatings. Since it is a liquid type and has good dissolving power, it is easy to handle and formulate. It uses unsaturated acrylic monomers as reactive diluents to initiate system polymerization. The usage rate of photoinitiator 1173 varies depending on system composition, light source, line speed and film thickness, but is typically between 0.5% and 5% w/w. The addition of photosensitizers such as ITX and DETX can greatly increase the curing speed. Photoinitiator 1173 can be used in printing inks, solder resists; overprint varnishes and wood paints, adhesives and photoresist dry films.

Storage conditions

Must be stored in a closed container in a dark and dry place.

Package

25kg plastic drum/200kg iron drum.

- PREV:Vertellus n-ODSA Succinic Anhydride Oily Corrosion Inhibitor Imide Monomer

- NEXT:Vertellus Coscat® 8330R Organobismuth/Zinc Catalyst