INV 7000-1 Efficient polyester hydrolysis resistance solution

physical properties

|

Exterior |

white or yellowish crystals |

|

density |

About 0.97g/cm³ |

|

melting point |

about 50℃ |

|

Viscosity |

16.0-24.0 mPa·s |

|

Solubility |

Soluble in organic solvents, such as acetone, dichloromethane, etc.; insoluble in water |

Product performance

INV 7000-1 can react the active terminal carboxyl groups produced by the hydrolysis of polyester molecular chain, prevent the further progress of hydrolysis reaction, thus effectively inhibit the decline of mechanical properties caused by hydrolysis, and greatly prolong the service life of the product.

Technical advantages

Adopt the latest synthesis technology, with better stability;

· High activity, fast reaction with carboxyl groups;

· High purity, no isocyanate residue;

· Better than similar foreign products, widely used.

typical application

· INV 7000-1 can be widely used in PU products, such as TPU, cast PU elastomer, PU adhesive, PU coating, PU shoe sole stock solution, PU microcellular elastomer, etc. The general dosage is 0.5-2.0 phr, It can significantly improve the hydrolysis resistance of the product.

· INV 7000-1 is generally applied to polyurethane system in molten state, and the processing temperature is not lower than 50℃.

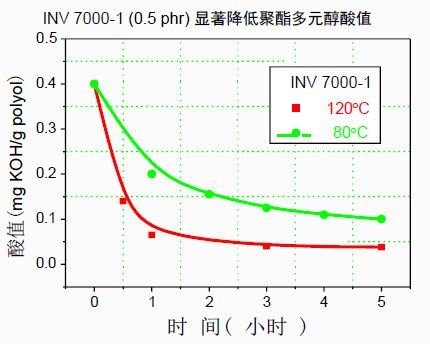

· Polyester polyols: The addition amount is 0.5-1.0 phr, which can rapidly reduce the acid value of polyols and improve the hydrolysis resistance of materials.

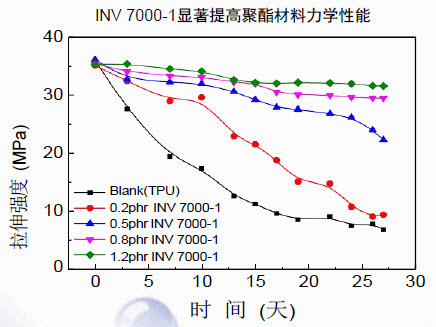

TPU: Adding different parts of INV 7000-1 to TPU, after a certain aging time, the tensile strength and elongation at break retention rate of the material are much better than those without adding INV 7000-1 (70 ℃ boiling test ).

storage stability

It can be stored for at least one year in the original packaging under airtight and dry conditions.

Packaging Specifications

10kg cold rolled iron drum or 25kg PE lined drum.

Security Information

See the Safety Data Sheet for the INV 7000-1.

- PREV:Covestro Desmodur BL 3175 SN heat activated HDI based curing agent for one-component polyurethane coatings

- NEXT:Germany Bruno Bock 2-EHMP 3-mercaptopropionic acid-2-ethylhexyl ester molecular weight regulator