Japan Shin-Etsu Silicone Resin

Silicone resin

Silicone resin is a resin composed of silicon-oxygen bonds (Si-O-Si) with high bonding energy. The layer has various properties such as heat resistance, weather resistance, electrical insulation, and water resistance.

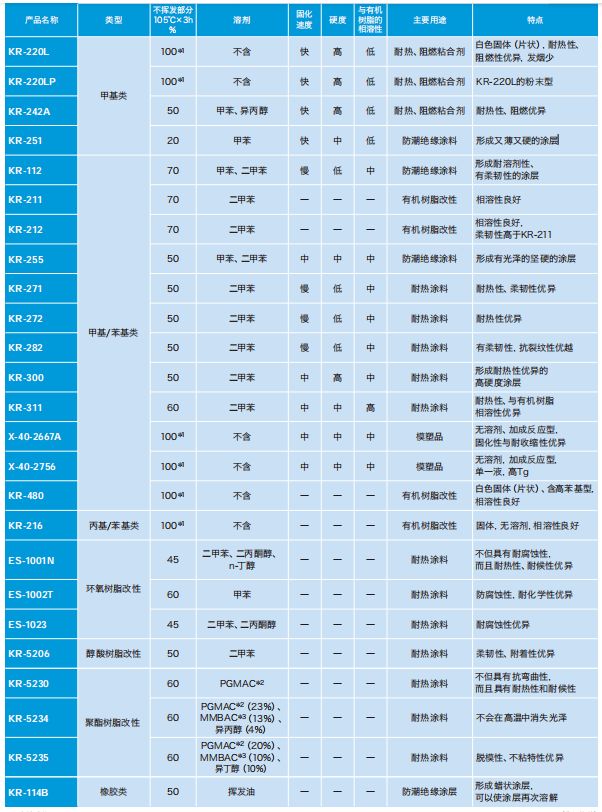

Methyl silicone resin: It is a silicone resin whose organic substituent is completely composed of methyl groups. Can form very hard coatings with moisture resistance, insulation, water resistance, and mold release properties

Methyl/phenyl silicone resin: It is a silicone resin whose organic substituent is composed of methyl group and phenyl group. It is possible to form coatings with excellent heat resistance, mechanical strength and gloss.

Organic resin modified silicone resin: it is a silicone resin mixed with other organic resins. coating.

application

(1) Heat-resistant coatings: Silicone resins are used as coatings in the temperature range (200°C or higher) that general organic resin-based coatings cannot use due to their heat resistance. In addition, because of its excellent weather resistance and water resistance, it has the characteristics of strong outdoor deterioration resistance and high affinity with ordinary inorganic pigments. Heat-resistant coatings are formed into a wide variety of products according to their application, material, temperature range, etc. Among them, silicone resins are widely used in many products.

Extended use: irons, rice cookers, pots, ovens, water heaters, kettles, around engines, heaters, exhaust mufflers, plant equipment

(2) Weather-resistant coating: The deterioration of the exterior coating is caused by ultraviolet light, high temperature, water, etc., and the gloss weakening and weathering will occur. Since silicone resins are not decomposed by ultraviolet rays, high temperatures, and water, they have excellent weather resistance compared to ordinary organic resins, and are used as letdowns for exterior paints.

(3) Used for resin modification: silicone resins containing a large amount of phenyl groups have excellent compatibility with other organic resins, and can impart various silicone properties. For example, flame retardancy can be imparted by adding KR-480 or the like during kneading to manufacture polycarbonate. From the viewpoint of environmental protection and safety, it is attracting attention as a material to replace the conventional antimony-based, halogen-based, and phosphorus-based materials.

(4) Electrical insulating coating layer: The silicone resin maintains a high volume resistivity above 1X10^13 Ω·cm in a wide temperature range from room temperature to 200 °C, showing excellent electrical insulation with small temperature dependence. performance. In addition, due to the direction of the methyl group on the surface of the coating, it has excellent low water absorption, and these characteristics are widely used in the protection of various electronic components

(5) Adhesives for heat resistance and electrical insulation: Silicone resins are used as adhesives for moldings such as metal powders because they are not softened by heat due to their excellent heat resistance and electrical insulation. Recently, with the spread of solar cells, HVs, and EVs, there has been an increase in demand as an adhesive for coil forming.